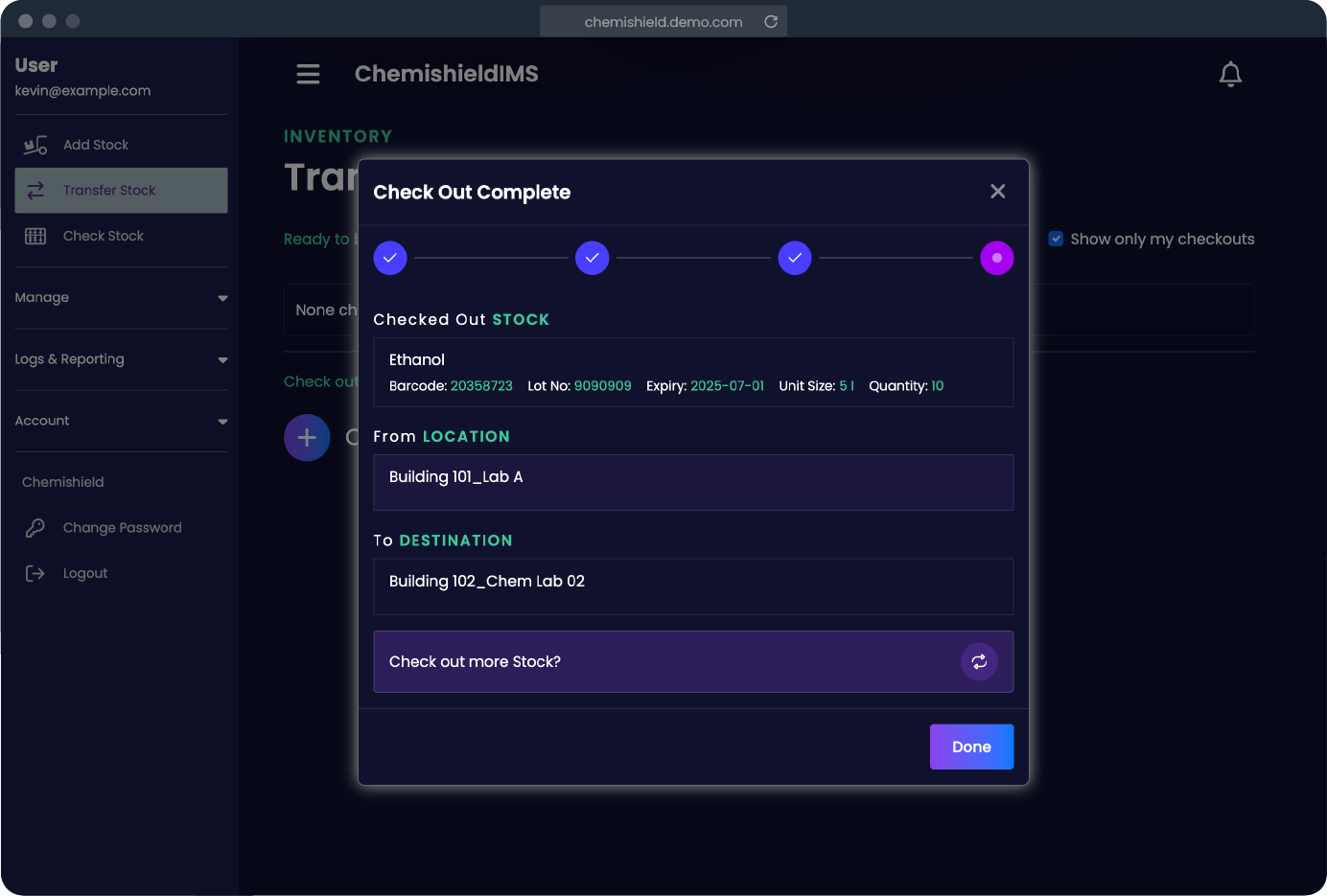

Manage storage locations across your facility

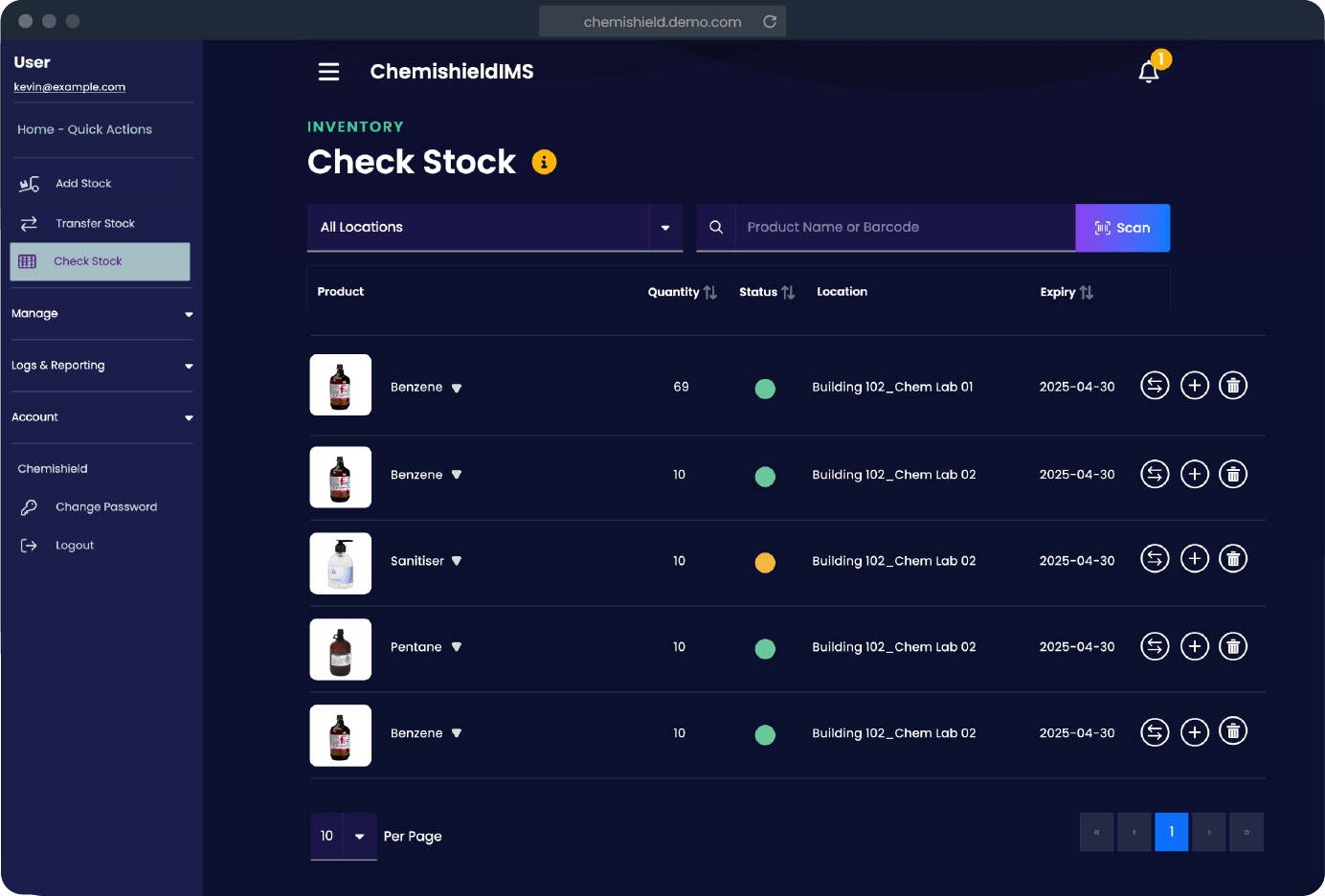

Full Control Of Inventory At Your Fingertips

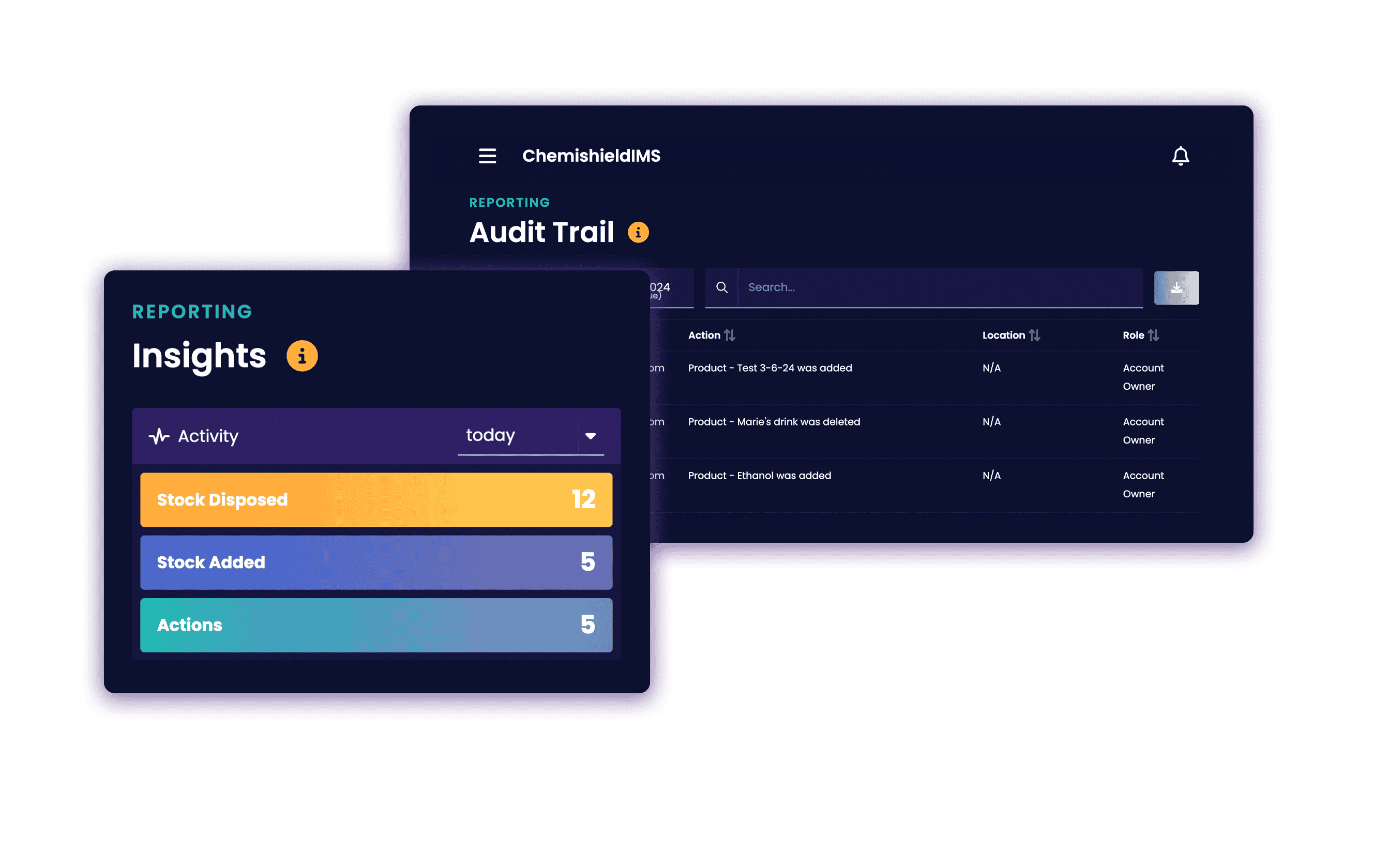

Inventory Reporting

Audit Trail

View inventory that is close to expiring or reaching a reorder limit. Export such reports for data driven decision making.

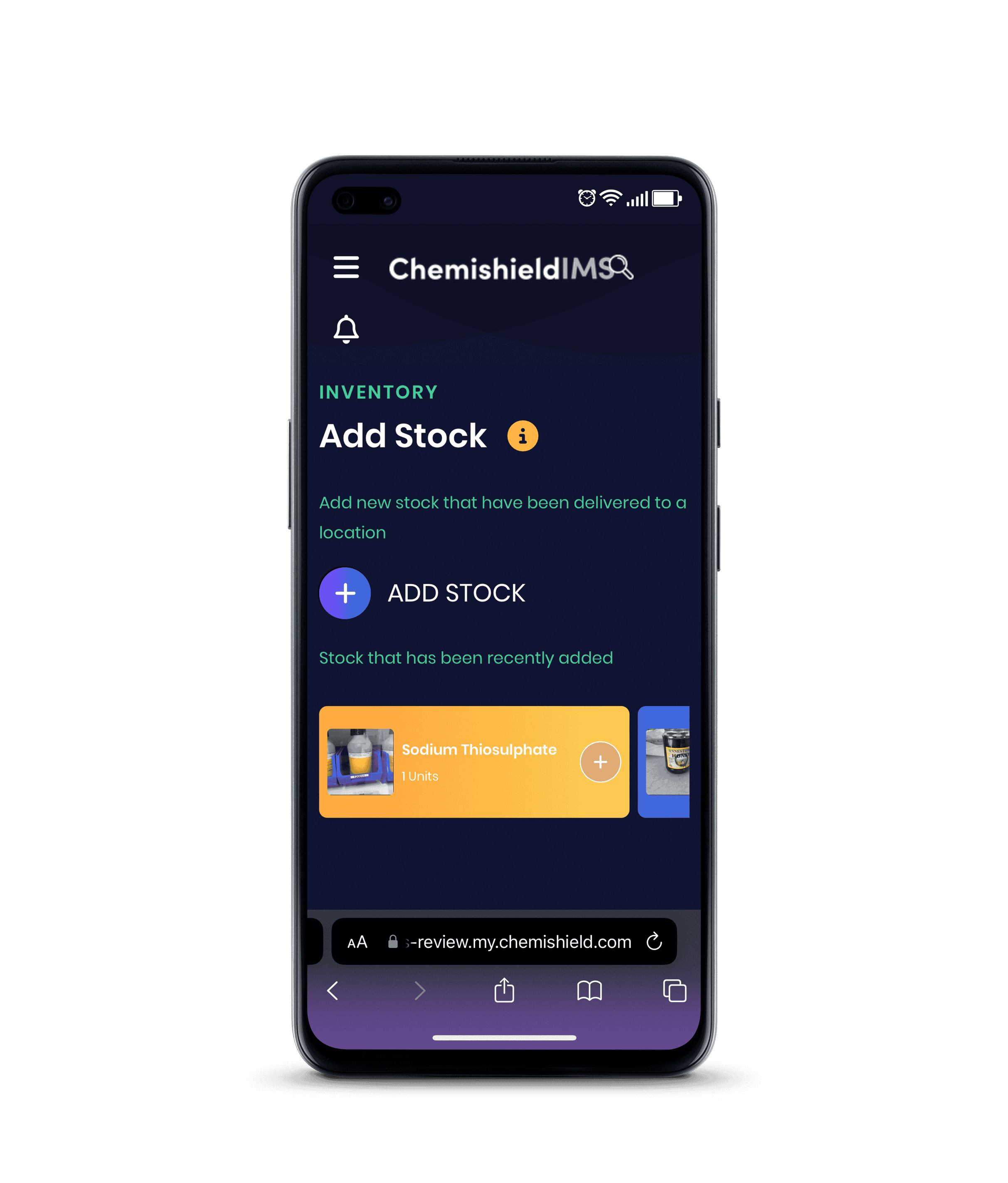

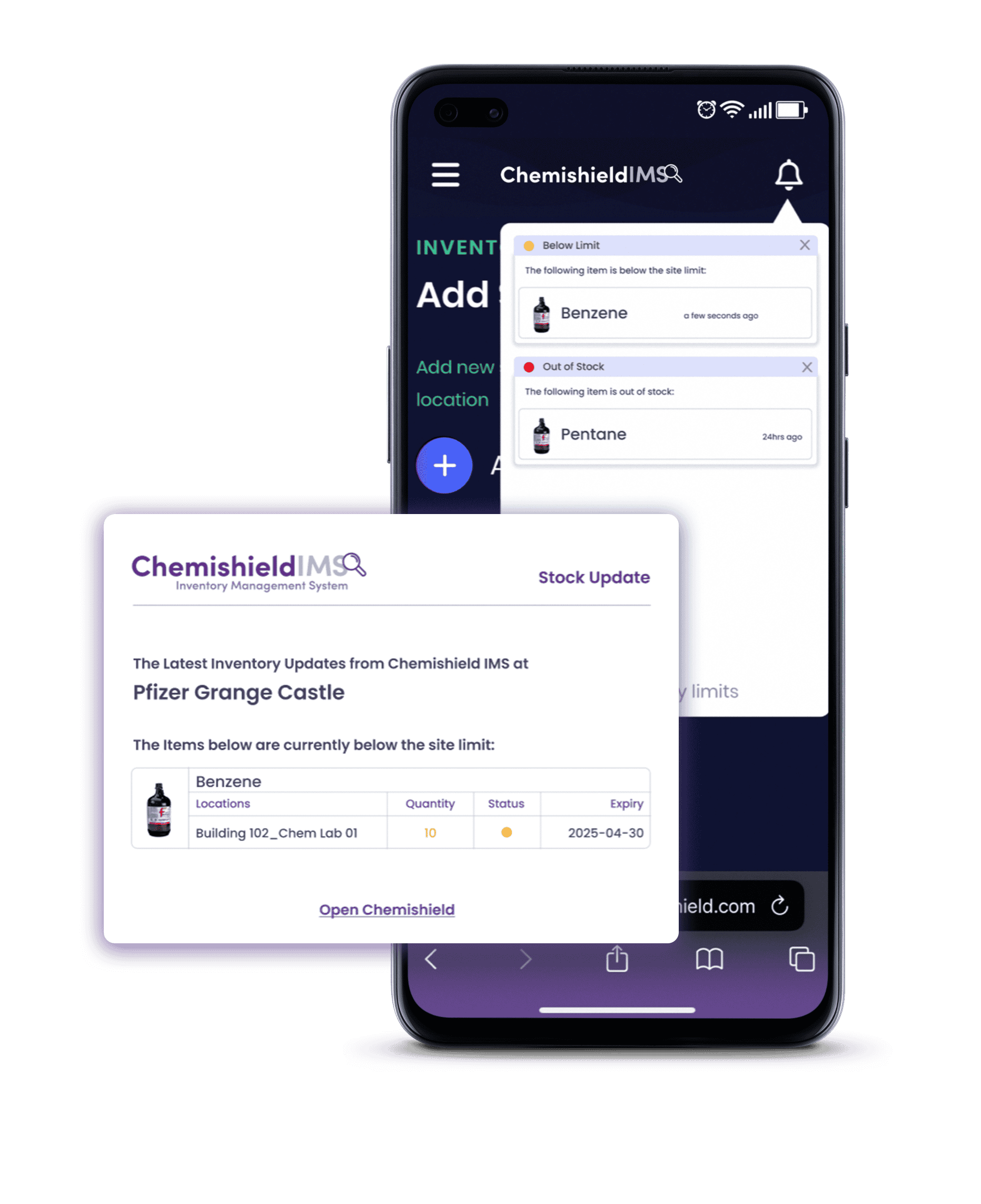

Your Inventory At Your Fingertips

ChemishieldIMS makes it easy to manage your inventory anywhere at any time. Available on mobile devices and laptops.

An Inventory Solution that Saves you Time and Money

Sick of throwing out expired goods and watching money go into the bin? With our alerts function a real time or scheduled notification will be sent as soon as an item approaches its expiration date.

Items can be ordered and re-stocked, ensuring your workflow is never delayed.

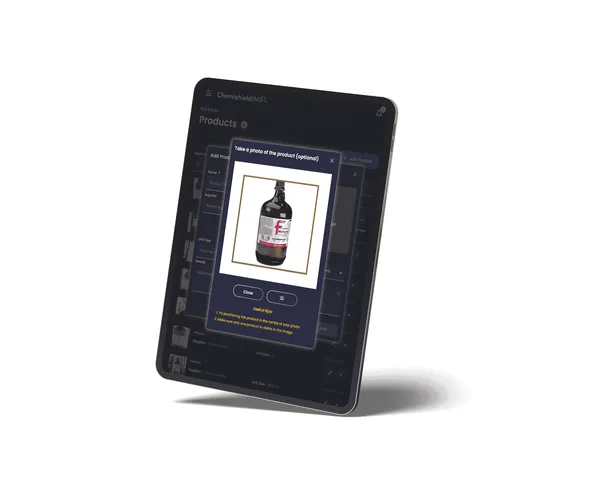

Identify Your Stock with our Reference Image System

ChemishieldIMS allows users to create a reference image for every item in your inventory, allowing future users to identify the right item in a matter of seconds.

will work for you

will work for you